Understanding Hemp Concentrate Extraction Methods

Hemp extraction processes are essential for creating a variety of cannabis concentrates. Each method, from solvent-based to rosin pressing, contributes uniquely to the final product’s quality and characteristics.

Hemp plants are rich in cannabinoids and terpenes, which are extracted through various methods to produce concentrates. These processes are crucial for maintaining the integrity and potency of the compounds, ensuring that consumers receive high-quality products. By exploring these techniques, you gain valuable insights into the art and science behind hemp concentrates, including the production of thca live rosin.

Introduction to Extraction Methods

Extraction is a fundamental step in the production of hemp concentrates. This process isolates cannabinoids and terpenes from the plant material, allowing for the creation of products that cater to diverse consumer needs. The choice of extraction method significantly influences the quality and efficacy of the final product. Understanding these methods is essential for making informed decisions about hemp-derived products.

Each extraction technique offers unique benefits and challenges. Solvent-based methods, such as using ethanol or butane, are known for their efficiency and high yields. However, they require careful handling to ensure no residual solvents remain. CO2 extraction, on the other hand, is favored for its safety and environmental friendliness, producing clean concentrates without harmful residues.

Modern extraction facilities employ sophisticated equipment and precise controls to maintain consistency across batches. Temperature monitoring, pressure regulation, and careful timing all play crucial roles in the extraction process. These facilities must also adhere to strict safety protocols and quality control measures to ensure their products meet industry standards and regulatory requirements. The evolution of extraction technology continues to drive innovation in the hemp industry, leading to more efficient processes and higher-quality concentrates.

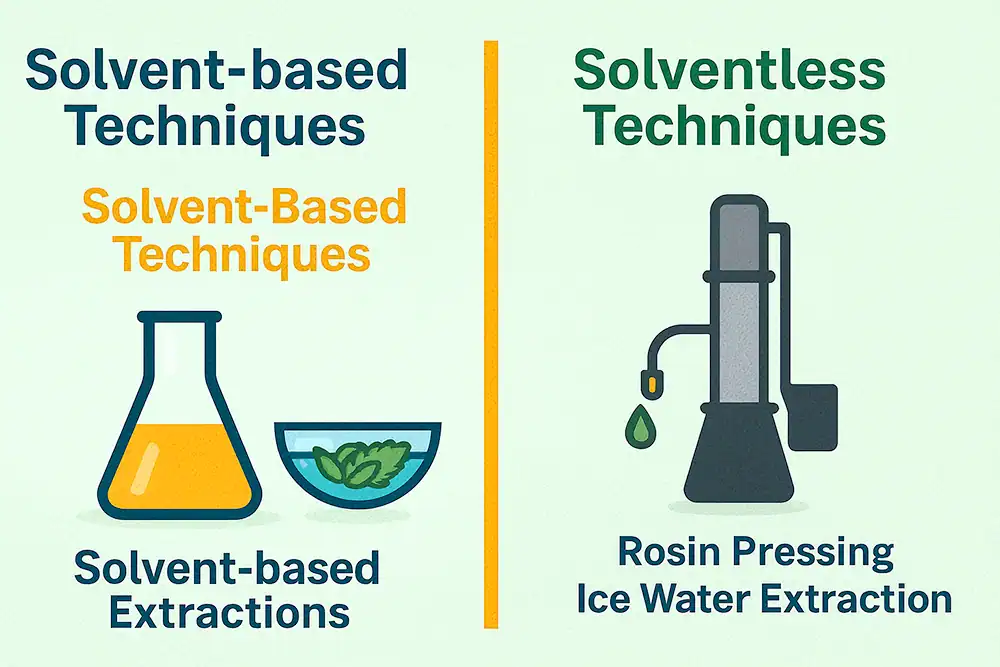

Solvent-based & Solventless Techniques

Solvent-based extraction involves using chemicals to dissolve plant materials and isolate desired compounds. This method is efficient and can produce high yields, but it requires careful handling to ensure the final product is free from residual solvents. CO2 extraction is a popular alternative that uses supercritical carbon dioxide to extract cannabinoids without leaving harmful residues. This method is environmentally friendly and allows for precise control over the extraction process.

Rosin pressing is a solventless method that applies heat and pressure to extract oils directly from plant material or hash. This technique preserves terpenes and offers a pure product free from chemical solvents. Rosin pressing is ideal for those seeking a natural concentrate with a robust flavor profile.

Ice water extraction represents another popular solventless method, where plant material is agitated in ice-cold water to separate trichomes from the plant matter. This technique, also known as bubble hash production, relies on the principle that frozen trichomes become brittle and easily separate from the plant. The resulting concentrate is then filtered through various micron screens to collect different grades of hash, offering consumers a pure, full-spectrum product that maintains the plant’s natural compound profile.

Characteristics of Hemp Concentrates

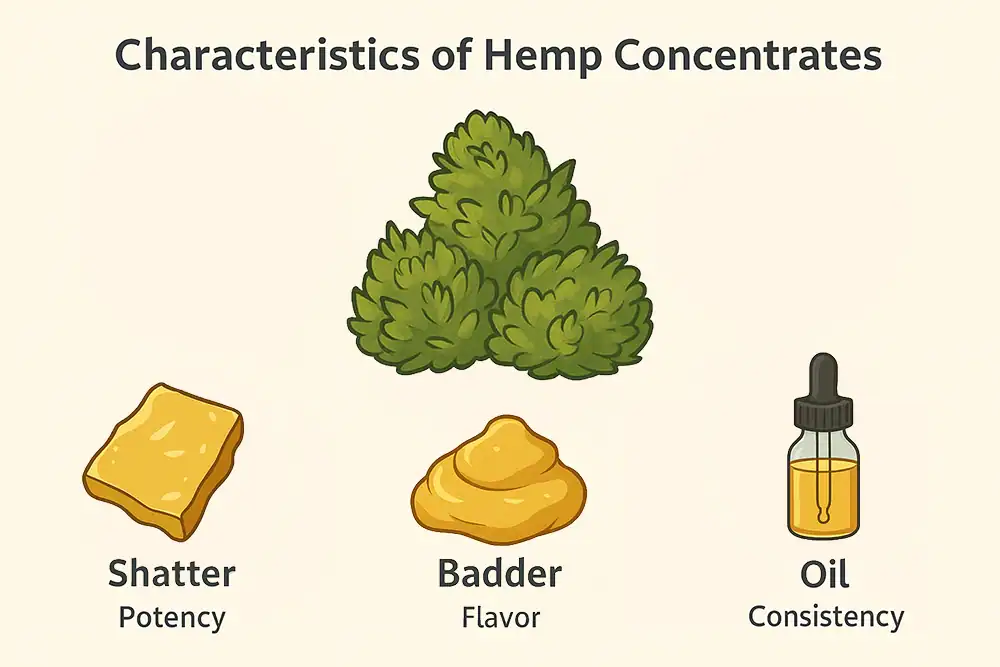

Hemp concentrates vary in their characteristics depending on the extraction method used. Solvent-based concentrates often have a higher potency due to the efficiency of the extraction process. However, solventless methods like rosin pressing are valued for their purity and natural flavor profiles. Understanding these differences helps you choose the right concentrate for your needs.

Each method offers unique advantages, from maximizing yield to preserving delicate flavors and aromas. As you explore these techniques, you gain a deeper appreciation for the complexity of hemp concentrates and the expertise required to produce them.

The consistency and texture of concentrates can range from glass-like shatter to butter-like badder, depending on post-extraction processing techniques. These variations not only affect the visual appeal but also influence how the concentrate can be handled and consumed. Factors such as temperature during processing, agitation methods, and the presence of lipids can all impact the final texture. Understanding these characteristics helps producers create products that meet specific market demands while maintaining optimal cannabinoid preservation.

Comparing Different Concentrates

When comparing hemp concentrates, it’s important to consider the production methods and resulting characteristics. Solvent-based concentrates may offer higher potency, while solventless options like rosin pressing provide a more natural product. Each type of concentrate has its own benefits, and understanding these differences can help you make informed choices.

By learning about the various extraction methods, you can better appreciate the nuances of hemp concentrates and their potential uses. This knowledge empowers you to select products that align with your preferences and needs, ensuring a satisfying experience with hemp-derived products.